Synkona

Synkona is a construction and industrial synthetic materials development company whose brands include Synkonabase® grouting systems, Synkonaseal® sealing and bonding systems, Synkonaultra® ultra-high performance concrete systems, Synkonarepair® concrete protection and reinforcement systems, Synkonasolid® flooring systems; based on twenty years of technical experience in building materials, the integration of the latest technology, Comprehensive range of polymer synthetic materials for buildings and industry;

Synkona's product and technical team provides professional services during the design and implementation of the project system, relying on the latest expertise to provide practical system solutions for the long-term safety of infrastructure, industrial, commercial and civil buildings; whether your project is a new construction project or a maintenance and renovation project on the basis of an existing building, please consult our team and we will find you the most satisfactory answer.

www. synkona.com

grouting

High performance equipment grouting

High-precision grouting

Building grouting

Wind power grouting

Prestressed pore grouting

Features and benefits

Based on years of practice in the field of professional grouting, we provide equipment feet for the equipment installation industry Bolt anchoring, and equipment base grouting systems; can be applied to static loads, general dynamic loads and High dynamic loads, etc., to reduce the impact of vibrations or weather changes. No shrinkage, fluidity Good, high strength, shock resistance and vibration resistance;

Recommended use

Steel structure column foot

Thermal power generation equipment such as turbogenerators and boiler feed pumps

Pulp and paper mainframe

Pumped storage power generation host

Nuclear power equipment

Tower cranes, gantry cranes

Heavy-duty compressors and pumps for the chemical refining industry

It is used in pumps and motors in the fertilizer, paper and chemical industries that come into contact with chemical contaminants

Offshore and onshore wind power grouting

Offshore wind power duct rack grouting

Achieve the best performance in an extremely volatile and harsh environment.

Temperature changes

Seawater environment

The role of waves and sea breezes

Freeze-thaw cycle

High resistance to fatigue

High final strength (80Mpa, 100Mpa, 120Mpa)

High modulus of elasticity

Underwater non-proliferation grouting

Offshore wind power booster grouting

Achieve the best performance in an extremely volatile and harsh environment.

Temperature changes

Seawater environment

The role of waves and sea breezes

Freeze-thaw cycle

High resistance to fatigue

High final strength (80Mpa, 100Mpa, 120Mpa)

High modulus of elasticity

Underwater non-proliferation grouting

Onshore wind power grouting

Construction under simple outdoor conditions to achieve high standards of performance.

Pre-packaged, out-of-the-box

Stir easily, just add water

Excellent flow

Strength grows fast

High final strength (80Mpa, 100Mpa, 120Mpa)

Shrinkage compensation

Durability, anti-fatigue

Pumped storage for power generation

Construction under a variety of conditions to achieve high standards of performance.

Pre-packaged, easy to stir, just add water

Excellent flow

Strength grows fast

High final strength (80Mpa, 100Mpa)

Shrinkage compensation

Durability, anti-fatigue

Pulp and paper making equipment grouting

Construction under a variety of conditions to achieve high standards of performance.

Pre-packaged, out-of-the-box

Stir easily, just add water

Excellent flow

Strength grows fast

High final strength (80Mpa, 100Mpa)

Shrinkage compensation

Durability, anti-fatigue

Chemical industry equipment grouting

Construction under a variety of conditions to achieve high standards of performance.

Pre-packaged, three-component mixing is easy

Excellent flow

Strength grows fast

High final strength (100Mpa)

Shrinkage compensation

Durability, anti-fatigue

Epoxy grout

Synkonabase-790

Three-component general-purpose high-performance epoxy grouting material

Cementitious shrinkage grout

Synkonabase-660 General purpose micro-expanding self-leveling cementitious grouting material

Synkonabase-680 Two-stage compensated shrinkage self-leveling high-strength cementitious grouting material

Synkonabase-6100 High strength fatigue resistant self-leveling cementitious grouting material

Synkonabase-6120 Ultra-high strength micro-expanding self-leveling cementitious grouting material

Synkonabase-6200 Underwater infusion type cementitious grouting material

Synkonabase-6300 Cement-based grouting material for general-purpose offshore wind power

Synkonabase-6400 Cement-based grouting material for ultra-high strength offshore wind power

Seal bonding

Adhesive surfacing agent

Adhesive for steel structures

Adhesive glue for precast concrete components

Epoxy resin injection slurry

Synkonaseal®480

Solvent-free two-component thixotropic epoxy structural adhesive

Solvent-free, two-component, thixotropic epoxy structural adhesives are used in the assembly of concrete components and for sealing and waterproofing, especially in applications where the bonded surface needs to withstand continuous stress.

Features and benefits

No sagging, suitable for applying on the top surface and façade, can be bonded to wet surfaces, can be easily used in areas that are difficult to dry treatment, hard, strong adhesion, withstand impact force; structural bonding, effective transfer of stress at the bonding interface, no creep, even at higher temperatures for a long time to withstand the load seal, provide water sealing effect at the seam, no sagging, the sagging of the bonding layer does not lead to the loss of bonding force Ultra-long opening time at high temperatures, can be calibrated and bonded for the calibration and bonding of components, excellent compressibility, Adhesives between components are effectively diffused and in contact.

Recommended use

Bonded to most surfaces

Fix loose or damaged tiles and masonry structures

Prefabricated components of bonded bridges & viaduct bridges

Concrete fan tower

As an external steel plate and carbon plate adhesive for beam/column/floor reinforcement

Anchor bolts, reinforcement, etc. in concrete

Port binder for steel pipes or concrete pipes used to transport water & sewage

Wind power mixed tower assembly

Construction under a variety of conditions to achieve high standards of performance.

Pre-packaged, easy to mix

Solvent-free two-component thixotropic epoxy structural adhesive

Assembly of concrete elements

Sealed and waterproof

Applications that require continuous stress

Thixotropic, durable, anti-fatigue

UHPC

UHPFRC reinforcement

Steel-UHPFRC combination bridge deck

UHPFRC prefabricated bridge

UHPFRC connection technology

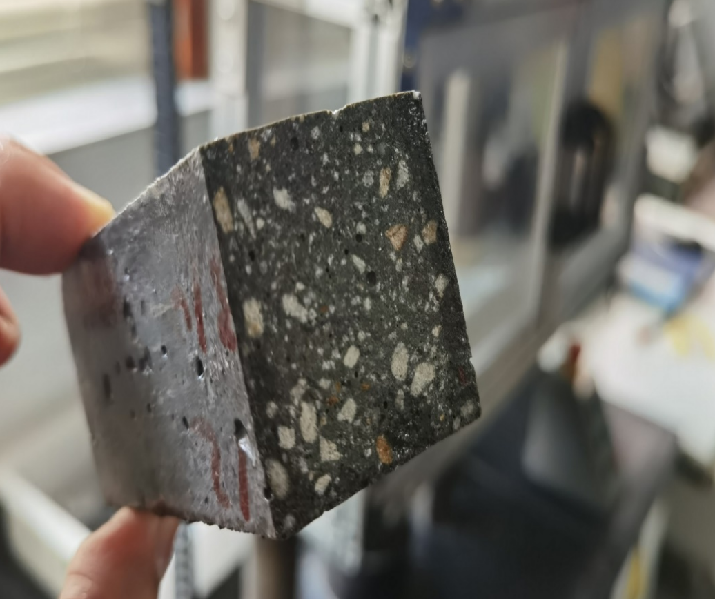

UHPC ultra-high performance concrete

UHPFRC reinforcement material

UHPFRC prefabricated mortar material

UHPFRC reinforcement

Effectively improve the bearing capacity of the original structure

The calculation is based on reasonable basis and the life is long

Suitable for concrete or steel structures

Steel-UHPFRC combination bridge deck

Reinforcement and studs are designed on demand,At the same time, it solves the two problems of steel bridge deck fatigue and bridge deck paving is easy to damage

UHPFRC prefabricated bridge

Reduces self-weight,mprove durability,Reduce carbon emissions

UHPFRC connection technology

Safe, reliable and leak-free,Accelerate construction

Features and benefits

Based on the principle of the tightest accumulation, the use of nanotechnology, through the precision formula design, the formation of a highly dense inorganic material, while improving excellent mechanical properties, has excellent anti-permeation, anti-freeze-thaw, corrosion resistance, high temperature resistance and other characteristics. The fibers uniformly dispersed in the matrix improve the characteristics of high tensile strength, strain strengthening of metals, high ductility, multi-point distribution of micro-cracks, and high explosion resistance and erosion resistance.HPC is a cement matrix composite material with optimal gradation of constituent material particles;The water-glue ratio < 0.25, containing a higher proportion of fine short steel fiber reinforced materials;Compressive strength ≥ 150MPa, with the toughness of the tensile state, and the tensile strength remains not less than 5MPa after cracking;The interior has a non-connecting hole structure, has a high resistance to gas and liquid intrusion, and can be greatly improved compared with traditional concrete and high-performance concrete. It has excellent properties such as ultra-high strength, high toughness, low permeability and high volume stability.It can be constructed in an environment of more than 5 degrees, without the need for steaming.

Recommended use

Steel deck paving

Wet seams

Bridge reinforcement

Quick repairs

Concrete protection and reinforcement

Concrete repair mortar

Bridge box plate reinforcement products

Underwater structural repair and protection

Structural protective coatings

Concrete silane waterproofing

Rapid pavement repair product system

Epoxy resin repair mortar

Features and benefits

Mechanism densification - reduces osmotic erosion in aggressive environments, pre-packaged - ready to use, thixotropic - no hanging fiber reinforcement occurs under the recommended thickness - can be used vertically or on top of buildings, high strength - high strength repair, no chloride - no corrosion of steel, sulfate resistance - advantages in sulfate/sulfide environment; high tensile and high winding resistance, effectively conducting the workload to the beam body, improving the bearing capacity of the beam body, maintaining high strength at high temperatures, even if the beam body as a whole can still effectively transfer loads at high temperatures, High early strength, open traffic in a short period of time, so that the traffic break time is shorter, high elastic modulus, the higher the elastic mold, the grout can withstand a greater load, while not deforming, high adhesion, effectively form an overall force with the beam body.

A thick paste-type epoxy resin protective coating specially developed to protect concrete and steel. Consisting of two components, a resin containing a dye and a curing agent, it needs to be stirred in the field to produce a decorative and chemically resistant coating that is easy to apply.

Recommended use

Maintenance of buildings at sea

Deep restoration of beams, columns and other structural components

Restoration of industrial buildings such as oil tanks, warehouses, chimneys, etc

Reinforced with condensing main box girder

Used for internal protection of concrete or metal sinks containing drinking water, specific chemicals, oils or fuels.

Chemically resistant floor and wall coatings.

Acts as an insulating layer for gases and vapors.

As a protective and decorative coating for areas such as laboratories, slaughterhouses, etc

Polluted areas for most industrial industries

Synkonarepair®160 Concrete silyl waterproofing

It is a selection of high-purity, non-dilutive isooctyltriethoxysilanes with a white paste appearance. The small molecular size ensures an effective depth of impregnation on concrete and stone building surfaces, allowing penetration into pore structures at the base layer. After infiltration, it reacts with moisture or gap moisture in the structure, forming a permanently bound hydrophobic layer with the matrix.

Features and Benefits

No sagging (thixotropy), good consistency, heavy use without loss, and ensure that the penetration depth is reduced, the absorbency is reduced, and the erosion dissolved in water is reduced

Absorption of sexual or hazardous substances (e.g. de-icing salts or chlorides in seawater environments)

The infiltration of water vapor does not have much effect and does not form a film

Ready-to-use, long-term effective, deep penetration

Improve the resistance of concrete to freeze-thaw cycle and de-icing salts

Resistant to seawater

Low volatile organic compound content

Recommended use

Recommended for most cement, stone and mineral substrates. Including: bridge plates, piers, docks, etc

Beams and columns of buildings

Exposed brick-concrete structure

Marine structures, high pile pile piles, etc

Floor

Cement base surface system

Epoxy floor system

Polyurethane floor system

Vinyl anti-corrosion system

Commercial and public buildings

Epoxy millstone flooring system

Elastic polyurethane flooring system

Cement base surface system

Food and great health

Polyurethane mortar flooring system

Epoxy sand mining self-leveling flooring system

Vinyl corrosion resistant floor system

Industrial and warehousing

Epoxy flooring system

Epoxy resin antistatic flooring system

Vinyl corrosion resistant floor system

Cement base surface hardener system

Recommended use

Factories, warehousing and logistics, heavy industrial facilities, hangars, shopping malls, supermarkets, shopping malls, parking plants;Food industry, medical and pharmaceutical industry, chemical industry, health and medical centers, restaurants, schools, officesOffices and museums; Improve the strength of the structure bearing dynamic load and static load, and add the durability and aesthetics of the bearing structure;

Whatever products you produce, store, sell or display; whether you, your family or your employees are in Where to work or relax, we focus on you carrying out your activities on high-quality ground.

Cement base surface system

Synkonasolid-120 Standard Load Mineral Aggregate Dry Sprinkler Ground Hardener

Synkonasolid-128 heavy duty alloy aggregate dry sprinkler ground hardener

Synkonasolid-126 HL liquid cement base hardening sealant

Epoxy floor system

Synkonasolid-220 two-component epoxy primer

Synkonasolid-260 Two-component epoxy thin coat textured layer

Synkonasolid-265 two-component epoxy artesian flat paint

Synkonasolid-267 Solvent-free epoxy color sand self-leveling series

Synkonasolid-260AS two-component epoxy antistatic topcoat

Polyurethane floor system

Synkonasolid-318 Super Hard Polyurethane Overlay System

Synkonasolid-345 Medium Self-Leveling Polyurethane Mortar

Synkonasolid-345AS Medium Duty-Free Self-Leveling Polyurethane Mortar

Synkonasolid-360 Heavy load polyurethane mortar floor material

Vinyl anti-corrosion system

Synkonasolid-320VAS ethylene resin anti-corrosion lamination system material

Synkona®Engineering Technology

Synkona provides professional-grade engineering service solutions for offshore conditions

Engineering and technology research and experimental development

Information Consulting Services

New material technology research and development

R&D of offshore wind power related systems

Project Management Services